Hall Effect Device by Palmer CRAIG

Hall effect

The Hall effect is the production of a voltage difference (the Hall voltage) across an electrical conductor that is transverse to an electric current in the conductor and to an applied magnetic field perpendicular to the current. It was discovered by Edwin Hall in 1879.

What is Hall Effect and How Hall Effect Sensors Work

The Hall effect is due to the nature of the current in a conductor. Current consists of the movement of many small charge carriers, typically electrons, holes, ions (see Electromigration) or all three. When a magnetic field is present, these charges experience a force, called the Lorentz force. When such a magnetic field is absent, the charges follow approximately straight paths between collisions with impurities, phonons, etc. However, when a magnetic field with a perpendicular component is applied, their paths between collisions are curved, thus moving charges accumulate on one face of the material. This leaves equal and opposite charges exposed on the other face, where there is a scarcity of mobile charges. The result is an asymmetric distribution of charge density across the Hall element, arising from a force that is perpendicular to both the straight path and the applied magnetic field. The separation of charge establishes an electric field that opposes the migration of further charge, so a steady electric potential is established for as long as the charge is flowing

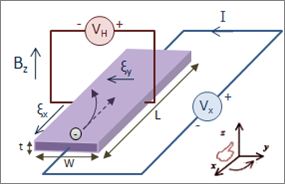

Hall effect measurement setup for electrons. Initially, the electrons follow the curved arrow, due to the magnetic force. At some distance from the current-introducing contacts, electrons pile up on the left side and deplete from the right side, which creates an electric field ξy in the direction of the assigned VH. VH is negative for some semiconductors where "holes" appear to flow. In steady-state, ξy will be strong enough to exactly cancel out the magnetic force, thus the electrons follow the straight arrow (dashed).

"Tubeless Receiver Claimed by Professor, Using Bismuth & Copper" by Robert Bangs

Recently it was announced at Mercer University (Macon GA), that the Westinghouse Electric & manufacturing Co. had offered Dr. Palmer H. Craig, head of the physics department of the university, $100,000 for a new device which is supposed to replace vacuum tubes as amplifiers and detectors.

The device is called an "electromagnetic detector and amplifier" and consists of a series of bismuth plates stacked in a pile and interlaced with copper wires. The bismuth plates are protected by a coating of sulfur because bismuth, a very brittle substance, is likely to crumble.

Long Sought After

Many attempts have been made by various investigators to make use in this manner of the this property of bismuth and of similar properties of allied metals but so far there has been no claim of success, until Dr. Craig came along. The most common attempted application is to the rectification of AC for filament and plate voltage supply. Lack of efficiency and of dependability have been the main causes of failure. Another limitation is the supply of suitable metals in commercial quantity.

One of the metals which displays similar properties is molybdenum. This has been used by scientists of the Bureau of Standards for converting light energy from the sun into electricity.

From Earth To Sun!

A certain amount of success has been achieved and it seems possible that power may soon be derived directly from the sun in this manner. Here, also, lack of efficiency and of adequate supply of the metal are limitations. There is plenty of molybdenum to be had in different parts of the world, but not all molybdenum is suitable for the purpose. There seems to be an active component in the metal which is responsible for the peculiar property, and it is now the aim of the scientists to isolate this substance.

Apropos the offer to Dr. Craig, Dr. Alfred N. Goldsmith, of the Radio Corporation of America, denied that any such offer has been made for Dr. Craig’s device. Dr. Goldsmith, chief broadcast engineer of the corporation, deprecates the idea that the peculiar property of bismuth can be used for the purpose claimed by Dr. Craig.

He is Not Yet Thirty

Dr. Craig emphasizes the point that the device will displace batteries as well as vacuum tubes in radio sets.

Dr. Craig, who is not yet 30, developed the invention, upon which he immediately applied for a patent, for his thesis at the University of Cincinnati where he received his degree of Doctor of Philosophy last June.

When asked to show the invention, Dr. Craig drew out a small block of substance resembling sulfur. It was an inch thick, about 3 inches long and 2 inches wide. Protruding from the top were tiny wires. It was encased except for the top.

He styled the device “an application of bismuth plates as detectors and amplifiers”, which could be used in place of present batteries and vacuum tubes in a radio.

What He Found Out

In his research for his Ph. D. degree at the University of Cincinnati, Dr. Craig found that the bismuth plates might be so used and the actual invention is described in part in his doctor’s thesis.

The inventor today spoke of the device as “a series of about 10 thin bismuth plates, piled one on the other, with wires running between them and finally on out to the actual radio set.”

Because of the delicate nature of the bismuth plates, Dr. Craig has protected them with a covering of sulfur. According to the inventor, the bismuth plates will generate the energy necessary to operate the radio and serve as a detector and amplifier.

Describes Process

The process is described in the scientist’s thesis as follows:

"The author is at present using this additive principle in an application of the Hall effect to rectification of alternating current, with a method similar to that described by Descoudres.

"The additive principle used in this connection produces a Hall potential of several volts in low fields with thin bismuth films, and thus gives the Hall effect a practical importance as a rectifier, especially in radio and similar applications."

Real Free Energy:

The Hall Effect in Bismuth with Low Magnetic Fields - by Palmer C. Craig - Physical Review 27: 772-778 (June 1926)

Abstract --- The Hall effect in bismuth for a magnetic field strength of from 0.07 to 1.00 gauss was accurately determined by improved methods. Production of the bismuth films. Various methods for obtaining excessively thin, homogenous bismuth films were tried and compared, such as casting, electroplating, evaporating, sputtering, and metallic spraying, of which the last three methods were particularly successful. Measurement of very low voltages. By refinements made in the potentiometer and measuring circuits, reading to one-tenth microvolt were accurate and reproducible. Magnitude of the Hall effect at low fields. The value of the Hall coefficient, R, is abnormally large between 0.07 and 0.30 gauss, having a value of -171 at 0.07 gauss, as compared with a value of -11 which R had for this film at 15 gausses. The value at 4220 gausses was -29, A curve is plotted showing the rapid decrease in the value of -R between 0.07 and 0.30 gauss, and comparison is made with higher values of field strength. It is noted that by putting the Hall potential of one film in series with one or more other films we obtain comparatively high values of the Hall emf, which may be applied to great advantage as an alternating current rectifier in radio and similar applications.

Introduction

Since the discovery of the Hall effect in 1875 much has been done to elucidate this phenomenon both experimentally and theoretically. But, with the exception of Righi (Ref. 1), who employed fields comparable to that of the earth, and a few others, almost all investigators have used strong fields. It is important to know accurately the effect of low fields, to compare it with the known facts and to determine whether any abnormal relations exist. As the effect of the magnetic field is small in all cases, a great refinement of the potentiometer and measuring circuits is imperative with weak fields, and the preparation of the bismuth strips presents great difficulties and requires special methods.

Preparation -- Experimental Arrangements

Since the Hall effect increases with the thinness of the metallic strips, the first requisite was to prepare extremely thin films of metal. Bismuth and tellurium, which have the highest Hall coefficient of the ordinary metals, were selected and six different methods were tried in order to find the best and quickest way of making films which would be extremely thin and at the same time electrically continuous. These processes were casting, dipping, spraying, electroplating, and sputtering.

Thin films of bismuth cannot be produced by casting unless pressure is exerted on the surface of the metal as it cools, and provision must then be made for lateral expansion when solidifying.

Surprisingly thin and uniform films were, however, obtained by dipping mica sheets into molten bismuth and using the metallic film which adhered to the mica. If the surface of the mica be slightly roughened with hydrofluoric acid, and care be used in withdrawing the mica from the molten metal, a very thin and uniform film can be obtained by this very simple and rapid method.

Much work was done by the author to produce very thin plates of bismuth and tellurium by the process of spraying molten metal. Excellent results were obtained both with the "Schoop" compressed air metallic spraying process, and also with the "Gravitas" metal dust spraying process. Cooperation in this part of the work was kindly rendered by the Metals Coating Company of Philadelphia. Both of these spraying processes involve spraying metals in the molten state by means of a compressed air gun. In the case of bismuth it was found advisable to use compressed nitrogen, instead of air, in order to prevent oxidation of the sprayed layer. When applied to mica, glass, and bakelite, excellent films of both bismuth and tellurium were obtained.

Attempts to produce homogenous films by electroplating met with poor results, even when great care was used regarding temperature, speed of the rotating cathode, and concentration of solution.

Evaporation of molten bismuth in a partial vacuum produced very good results. Bismuth was placed inside an evacuated bell-jar and was melted by an electric heater. A glass plate, suspended above the arrangement, collected the evaporated bismuth in the form of excellent films.

Cathodic sputtering undoubtedly produces the thinnest films of any method. With reasonable care bismuth films can easily be prepared by this method so thin as to be quite transparent. Sputtering was accomplished by applying the secondary current of a 20,000 volt transformer to anode and cathode electrodes placed inside a bell-jar evacuated to 30 microns. Rectification of the secondary current by a kenetron accelerated the action. A disc of bismuth 3.5 inches in diameter was used as a cathode, and the glass plate on which the film was to be sputtered was placed just outside the Crookes’ dark space, which was about 2 cm long. With a current of 5 milliamperes excellent films were produced on glass in about 20 minutes.

Disposition of the Apparatus

The very weak magnetic films employed in this work were obtained from an air core solenoid. When a given current is passed through such a coil the field at the center is easily calculated. This calculated value was checked by a calibrated ballistic galvanometer in conjunction with a flip coil. The actual coil employed consisted of 100 turns of wire wound on a rectangular wooden form 8 x 11 cm in cross-sectional area, the size of this form being just large enough to accommodate the film used. The inductance of this coil was 2.5 millihenries, and it was therefore necessary to pass 35.2 milliamperes through it in order to get a field of one gauss at the center. Because of the extremely low values of the magnetic field used, it was necessary to shield the arrangement carefully from any action of the earth’s and stray fields. Several methods were tried to accomplish this shielding, the one finally adopted being that of placing the set-up so that the plane of the bismuth field coincided exactly with the magnetic inclination of the earth’s field at that point, thus eliminating any magnetic component in a direction perpendicular to the plane of the magnetic film. Care was taken to keep all iron away from the vicinity of the apparatus, and upon actual measurement stray fields were found to be negligible.

Chemically pure bismuth for producing the films was furnished by Eimer and Amend and the film itself, obtained by any one of the previously described methods, was mounted on bakelite with sodium silicate as a binder. Contact at the ends for the longitudinal current was made by phosphor-bronze spring clips, and contact at the edges of the film, for picking up the transverse Hall potential, was obtained by means of small brass fingers attached to machine screws passed through the bakelite. The surface of the film was carefully cleaned with weak hydrochloric acid solution to remove surface oxides, and the entire film and connections were then painted with sodium silicate to keep semi-conducting layers of dirt and moisture from collecting on the surface of the film. In some cases it was even found advisable to mould the entire arrangement in sulfur to obviate this difficulty.

Since the potential differences to be measured were of the order of one microvolt, extreme care was taken to render the measuring apparatus very accurate and stable. The transverse Hall effect potential was measured by means of a Leeds and Northrup type K potentiometer, redesigned with a system of calibrated external shunts which increased the sensitivity of the instrument 10 times. Four galvanometers of varying degrees of sensitivity were used with potentiometer for null readings, the most sensitive galvanometer having a sensitivity of 12.2 mm per MV. The longitudinal current through the film was supplied by large storage cells, the output of which passed through a large filter system of two very large inductances in series with the line, the lines being shunted by two condensers of 6 microfarads each. This filter eliminated erratic action caused by sudden fluctuations of the longitudinal current occasioned by bubbling of the cells.

The main current through the potentiometer itself was passed through a similar filter and was allowed to flow overnight before taking readings so that greater stability could be expected. The null potentiometer reading on the standard cell was checked before and after and after each measurement.

Greater care was taken to eliminate all spurious effects. Thermal effects, of course, construed the greater part of these corrections. Junctions of dissimilar metals in the circuit were reduced to a minimum, and the remaining potentials due to Thomson and allied effects were accurately measured the instant the longitudinal current was broken. Grounding one side of the potentiometer circuit was found to increase stability.

For the work at high magnetic fields, a large electromagnet was used. This magnet was capable of producing a field of 18,000 gausses in a narrow air gap, the field of which was measured by a calibrated ballistic galvanometer in conjunction with a flip coil.

Experimental Results & Discussion

Using a bismuth film obtained by metallic spraying, 3.5 x 8.0 cm in area and 0.012 cm thick, the results shown in Table I were obtained. These results are in agreement with those obtained with films of the other type described previously. In this table three different ranges of magnetic field strength were investigated with the same bismuth film and under the same general conditions. A longitudinal current of 1.5 amperes was used throughout Table I. The "residual" emf (measured in microvolt) which is referred to in the second column is the potential difference caused by the fact that the brass fingers which pick up the transverse Hall potential cannot possibly be placed at exact equipotential spots with regard to the longitudinal current. These contacts were placed as near to equipotential points as possible and the remaining difference of potential was measured as given in the second column of the table. The second and third columns automatically include the sum of the thermal effects, since it is of course impossible to eliminate the thermal potentials from the potentials indicated in these columns. However, the spurious effects are eliminated when column two is subtracted from column three in order to get the net Hall emf in the fourth column. The Hall coefficient, R, given in the fifth column is calculated from the usual formula (Ref. 2),

R = Ed / IH ,

Where R is the Hall coefficient, d the thickness of the film in centimeters, i the longitudinal current in abamperes, H the magnetic field strength in gausses, and E the net Hall emf.

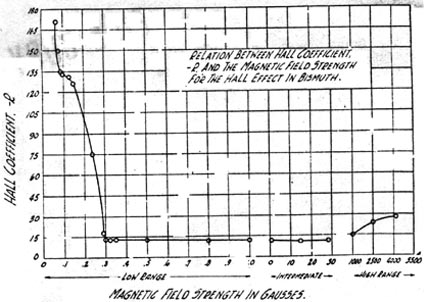

Figure 1: Relation between Hall coefficient, -R and the magnetic field strength for the Hall effect in bismuth

It is immediately apparent that the Hall coefficient is abnormally high in the range of very low fields, and falls rapidly in value as the field is slightly increased. Reference to the graph (Figure 1) shows a slight irregularity near 0.1 gauss, a straightening out of the curve at about 0.3 gauss, and then an approximately linear relation until a field strength of 1.0 gauss is reached. Reading s in an intermediate range of zero to 30 gauss showed that -R is practically constant at a value of 10.27 which Von Ettingshausen and Nernst found for bismuth at a field of 1650 gausses. In the range from 1000 to 4200 gausses the coefficient increases slightly from 15 to 29. This curve was selected from a dozen similar graphs as being one of the most representative, and the irregularity in the neighborhood of 0.1 gauss is typical of similar irregularities in all curves obtained with the various films.

These results show that the value of -R at very low fields is higher than has been heretofore suspected and that the curve for -R, plotted against field strength, shows a marked rise in this low range.

Each of the values in Table I are average values for approximately 12 readings at each value of field strength. These readings are reproducible to approximately one-tenth of a microvolt, and the readings forming the averages did not vary more than this amount.

Table I: Hall effect in bismuth for low, intermediate and high fields

Gausses Residual emf Residual + Hall emf Net Hall emf -R

0.07 14.0 microV 15.5 microV 1.5 microV 171

0.08 14.1 15.6 1.5 150

0.09 14.2 15.7 1.5 135

0.10 14.2 15.8 1.6 133

0.13 14.4 16.1 1.7 131

0.15 14.3 16.9 2.6 126

0.24 14.0 16.3 2.3 75

0.29 14.6 21.1 6.5 18

0.30 14.5 19.8 5.3 14

0.32 14.4 19.6 5.2 13

0.35 14.8 20.5 5.7 13

0.50 14.6 22.7 8.1 13

0.80 14.6 26.6 12.0 12

1.00 14.6 29.6 15.0 12

1.0 14.5 29.5 15.0 12

15.0 14.3 35.1 20.8 11

28.5 14.4 60.4 46.0 11

1000 14.0 1889.0 1875.0 15

2500 14.0 7514.0 7500.0 24

4220 14.0 15324.0 15310.0 29

During the course of the experiments an interesting incidental fact was discovered, namely that the Hall effect of one film may be put in series with that of one or more other films, the sum of these series potentials agreeing very well with the calculated sum of the Hall potentials of the individual films as observed separately. Although this fact has little application where quantitative readings of a high degree of accuracy are desired, it is of real importance in any application where larger values of Hall potential are desirable than those which can be obtained with a single film. The author is at present using this additive principle in an application of the Hall effect to rectification of alternating current with a method similar to that described by Descoudres (Ref. 4). The additive principle used in this connection produces a Hall potential of several volts in low fields with thin bismuth films, and thus gives the Hall effect a practical importance as a rectifier, especially in radio and similar applications. Work on the additive principle is also being done by Sarek (Ref 5).

The results here presented indicate that there is considerable work to be done in further investigating abnormalities in the Hall coefficient at very low fields, and also suggest that certain modifications or explanations will have to be introduced into the theory of the Hall effect to account for the interesting changes in the Hall coefficient at low fields.

In conclusion, the author wishes to acknowledge his indebtedness to Dr. Louis T. More, Dr. R.C., Gowdy, and Sr. S.J.M. Allen for their kind help and valuable advice tendered throughout the progress of the work.

Ref. 1 ~ Righi: Journale d. Physique 3: 127 (1884)

Ref. 2 ~ L.L. Campbell: "Galvanomagnetic & Thermomagnetic Effects", p. 9

Ref. 3 ~ Von Ettinghausen & Nernst: Wied. Ann. 29: 343 (1886)

Ref. 4 ~ Des Coudres: Phys. Zeitschrift 2: 586 (1901)

Ref. 5 ~ Sarek: Eleck. U. Maschinenbau 43: 172 (1925)

System & Apparatus Employing the Hall Effect - Palmer H. Craig - U.S. Patent 1,822,129 (Sept. 8, 1931)

My invention relates broadly to electrical apparatus for modifying the behavior of electrical current and more particularly an apparatus for effectively employing the transverse potential difference in certain metallic plates when subjected to the action of a longitudinal current and the influence of a magnetic field.

One of the objects of my invention is to provide a device consisting of a plurality of rectangular metallic foil sheets or metallic alloy plates in stacked arrangement insulated one from another and electrically connected in parallel at opposite ends thereof and in series along the transverse axis thereof, whereby current of direct current characteristic may be secured in a circuit which connects to points along the transverse axes of the plates when alternating current is supplied to the opposite end of the plates and a magnetic field created around the plates.

Another object of my invention is to provide a construction of fixed rectifier for alternating current which remains in permanent adjustment and does not require resetting from time to time.

Another object of my invention is to provide a device for modifying electrical current of alternating characteristic for rectifying, amplifying, or causing the generation of electrical oscillations of any selected frequency.

Still another object of my invention is to provide an electrical apparatus particularly adapted for operation in conjunction with the circuits of a radio receiving system for rendering feeble signal currents observable.

A still further object of my invention is to provide an apparatus unit which may be connected in circuit with electron tube apparatus for facilitating the operation of the electron tube apparatus in the reception of signaling energy.

Other and further objects of my invention will be understood from the specification hereinafter following by reference to the accompanying drawings in which:

Figure 1 represents in perspective view the arrangement of parts in the apparatus of my invention; Figure 2 is an end view of the apparatus showing more clearly the direction of the magnetic field perpendicular to the plane of the metallic plates; Figure 3 is a schematic view showing the arrangement of the metallic films which comprise the apparatus of my invention; Figure 4 is a diagrammatic view showing the wiring arrangement of the apparatus of my invention when used as a rectifier; Figure 5 shows one of the applications of my invention in a reflex signaling receiving circuit; Figure 6 illustrates an application of my invention as a detector in a radio circuit; Figure 7 shows a circuit arrangement which makes use of the principles of my invention in the amplification of signal energy, provision being made for facilitating the production of oscillations; Figure 8 shows a circuit arrangement wherein the longitudinal current which passes through the plates of the apparatus of my invention is derived from a source independent of the source which creates the magnetic field about the plates; Figure 9 illustrates a circuit arrangement employing a plurality of the devices of my invention as an amplifier of incoming signaling energy and as a rectifier of the amplified energy; and Figure 10 shows the fundamental arrangement of the magnetic field transverse to the plane of several metallic plates in the apparatus for developing the principles set forth herein.

Figure 1:

Figure 2:

Figure 3:

Figure 4:

Figure 5:

Figure 6:

Figure 7:

Figure 8:

Figure 9:

Figure 10:

My invention makes use of the "Hall", "Corbino" and similar electromagnetic phenomena for the rectification or amplification of alternating currents, and the generation of sustained electrical oscillations in electrical circuits.

The "Hall" effect consists, briefly, of an electromagnetic phenomenon observable when a strip or film of metal carrying a longitudinal current I, (Figure 3) is placed in a magnetic field perpendicular to the plane of such a strip, a transverse potential difference being set up between the edges a, a’, of the strip, this difference of potential being approximately, under normal condition represented by the formula:

E = HI/d

Where E = the transverse potential difference;

I = the current (longitudinal) through the strip;

d = the thickness of the strip;

H = the magnetic field strength

The "Corbino" effect is similar to the "Hall" effect, wherein a radial current through a circular disc subjected to a magnetic field perpendicular to the plane of the disc, produces a "circular" current through the disc.

I have discovered that if plates or films of metal such as bismuth, tellurium, bismuth-antimony alloy, or other metal or alloy, be connected as shown in the drawings, the devices will act as a practical electrical rectifier of impressed alternating currents. Refering to the drawings in Figure 4, the alternating current is sent through the strip 1 from c to d, in one-half of the cycle, and from d it enters the solenoid S, being an air-core or a core of magnetic material, thence after passing through the solenoid it returns to the alternating current source. In the other half of the cycle the operation is, of course, reversed.

Figure 4 also shows the method of stacking many plates 1,2 and 3 on top of one another, with suitable insulation between, and then connecting the positive "Hall" effect potential point of one plate to the negative "Hall" effect potential point of the one below, as represented in the drawings at e, f, g, h, i, and j. In other words, the transverse potential of all the plates 1,2 and 3 are put in series in order to add up to larger values of potential than would be obtained with a single plate.

It is obvious, that since the polarity of the "Hall" effect potential difference changes in synchronism with either the change in polarity of the points c and d, or with the change in direction of the magnetic flux through the plate, the polarity of the point e, j (Figure 4) will always be the same with respect to each other when both the magnetic flux and also the longitudinal current through the plates change in phase synchronously with each other, The arrangement shown in Figure 4 will then obviously give a pulsating direct current at the point e, j.

The construction of the apparatus of my invention is more clearly illustrated in Figure 1 where the metallic films have been represented at 1, 2, 3, 4 and 5 separated by insulated sheets 7. Opposite ends of the films are tapped as represented at c and d. The transverse axes of the films are connected in series as represented at e, f ,g, h, i, j, k, l, m, and n for delivering a direct current. The end view of the apparatus in Figure 2 shows more clearly the arrangement of the films and the dielectric sheets. The solenoid winding has been divided into two sections for producing a transverse magnetic field through the metallic films.

In Figure 3 I have shown a stacked arrangement of metallic films separated by insulated sheets in accordance with my invention, where the alternating current I passes along the longitudinal axes of the films from d to c. I provide copper end contacts 8 and 9 which bridge all of the metallic films enabling the films to be connected in the electrical circuit in parallel. The point contacts across the transverse axes of the films have been represented at a and a’.

The device may be used as a rectifier in ordinary electrical circuits where the power drawn from the rectifier is of sufficiently low value as to render the method practicable. The arrangement can also be used as a rectifier in radio transmitters and receivers, especially to replace the crystal detector or the triode vacuum tube detector in radio reception. It could be used either alone or in combination with electron tubes, a typical circuit diagram of the latter method being given in Figure 5.

Referring to Figure 5 in more detail the receiving antenna system is represented at 10 which connects to a ground system at 11 with a coupling inductance 12 therein coupled to the tuned input circuit 14 of the electron tube 15 which functions as a radio frequency amplifier. The output of the radio frequency amplification circuit 16 with the input circuit of a second stage of radio frequency amplification constituted by electron tube 18, the output circuit of which includes transformer system 17tuned as represented at 28 for supplying exciting current to solenoid S through a series circuit which passes through the longitudinal axes of the metallic films from points d to c. A direct current is derived across the points of contact a and a’ which is directly proportional to the incoming signaling energy. The rectified current is delivered through a transformer system 20 to the input circuit of the electron tube 18 which also functions as an audio frequency amplification system delivering its audio frequency output through transformer 19 with the input circuit of electron tube 15 which serves also to amplify at audio frequency delivering its output to telephones T. Battery A supplies filament heating current for the several tubes while battery B supplies space current for the tubes. The tuned system 17-28 permits a relatively large value of current to pass through the metallic films and thereby secure maximum direct current energy across the transverse axes of the metallic films. My invention may be applied to all standard circuits as well as to the reflex system of Figure 5.

Referring to Figure 6 a simplified circuit as illustrated showing the application of the principle of my invention to a simple radio receiving apparatus. In this circuit the incoming signaling energy delivered from tuned circuit 14 passes through the longitudinal axes of the metallic films from d to c at the same time setting up a magnetic field by means of solenoid S for deriving direct current across the transverse axes of the metallic films at a and a’ proportionate to the incoming signal energy. This direct current directly actuates the telephone responsive device T.

It should be noted that, due to the fact that this system is a perfect rectifier (that is, it admits of no inverse potential or currents in the output) it will produce no distortion in the reproduction of radio telephone signals and voice, and is, therefore, far superior to either the crystal detector or the electron tube from the standpoint of faithful reproduction, in addition to its superior qualities of stability, ease of operation and lower cost of maintenance.

Figure 7 illustrates a circuit arrangement which I employ in the amplification of signaling energy by means of the apparatus of my invention. An input circuit has been illustrated in the form of an inductive coupler 25 tuned by variable condensor 26 and connected through the longitudinal axes of the metallic films at d and c. A permanent magnetic field may be established about the metallic films by means of a local source 21 connected in circuit with the winding S. An iron core may be provided for this solenoid S. Incoming signaling energy is supplied through winding 27 coupled with the windings 25. The transverse axes of the films at a and a’ are connected in series with a local source 22, and an inductance 24 which couples with the inductance system 25. A desired degree of regenerative amplification is thus introduced for increasing the amplitude of the impulses of signaling energy delivered to the output circuit. The principle of my invention may be applied to an oscillator where the input coil 27 connects to a small local exciter of alternating current and the output connected through a transformer system. By employing selected values of inductance, capacity and resistance the system may be arranged to oscillate at either audio or radio frequencies.

Figure 8 illustrates a method of obtaining greater energy amplification in the apparatus of my invention. A permanent magnetic flux is set up through the thickness of the plates and also a permanent longitudinal current is established along the horizontal axes of the plates from a battery 28. A tuned input circuit system 27-25-26 is arranged to excite the winding s which encloses the stack of alternately positioned films and dielectric sheets. The longitudinal axes of the films are connected at points a and a’ with an output circuit including a source of potential 22, and inductance 24. The inductance 24 is inductively coupled to an inductance 29 tuned by means of condensor 30 in the output circuit of the electrical system. The fluctuating magnetic field from the winding S which varies in proportion to the amplitude of the signaling energy is superimposed on the permanent field which is established.

The input may also be superimposed on the longitudinal current instead of upon the magnetic field. The local battery for supplying longitudinal current to the conductive field may thus be eliminated. The local battery 22 in the circuit of the electrical system is provided to boost the voltage of the output to a proper value for the operation of the succeeding amplifier stages or the reproducing unit, the "Hall" fluctuating potential being then superimposed upon this steady potential. By increasing the number of conductive films in parallel the effective potential may also be increased.

In Figure 9 I have shown an application of my invention to an electron tube circuit where the conductive films have their longitudinal axes connected in series in the output circuit of electron tube 15. A constant magnetic field is supplied from battery 21 to the winding S. In this manner the device operates as a radio frequency amplifier, delivering amplified energy to an output circuit across the transverse axes of the conductive films in series as represented at e and j, the output circuit including battery 22 and solenoid winding S’. The solenoid winding S’ connects in series with the longitudinal axes of conductive films as represented at c’ and d’ and across the transverse axes at a and a’ I connect the output circuit which includes the battery 22. The arrangement of the conductive films within the solenoid winding S’ serves as a rectifier of amplified energy delivered by the conductive films within the solenoidal winding S’.

Figure 10 shows a method I may employ for setting up the magnetic field which threads through the conductive films. A pair of compressed silicon steel filing cores or other suitable magnetic material or alloys are arranged on opposite sides of the stack of alternately positioned conductive films and dielectric sheets. On these coils are provide the windings S2 and S3 supplied from the local source 21. The stack of bismuth or metallic alloy conductive films may be quite thick but the magnetic field is concentrically normal to the plane of the conductive films. The magnetic field in some cases is produced by a solenoidal coil of approximately 1000 turns on cores of compressed silicon steel filings. The resultant transverse pulsating direct current is several volts for only one milliampere flowing through the field coil and longitudinally through the conductive films in parallel. I have found that where four amperes alternating current at 60 cycle frequency is passed through a 12 turn coil and then through the conductive films connected in parallel with themselves longitudinally, the resulting pulsating direct current component across each conductive films is approximately 50 microvolts. When the conductive films above referred to are connected in series transversely 200 microvolts may be obtained. The values obtainable may readily be used in the operation of electron tubes. The arrangement of the apparatus is such that connections may be readily made with electron tube circuits as represented at Figure 9 without their interposition of transformer systems.

When an iron core is used with the device of my invention with the proper permeability curve an asymmetric characteristic curve may be obtained with the device similar to that obtained with a triode tube. This ability of the device of my invention facilitates the generation of self-oscillations in the device. The device when properly connected will, therefore, operate as an amplifier or as an oscillator in addition to its properties as a rectifier.

While I have described my invention in certain preferred embodiments, I desire that it be understood that various modifications may be made without departing from the spirit of the appended claims.

Other U.S. Patents by Palmer Craig:

U.S. Patent 1,778,796 (Oct. 21, 1930): System & Apparatus Employing the Hall Effect

U.S. Patent 1,825,855 (Oct. 6, 1931): System & Apparatus Employing the Hall Effect

These patents largely repeat the claims of USP #1,322,129.

Summary of operation of Searl Effect Generator:

- The rotating permanent magnet is the stirring of the Ether. The generator does not generate electricity, it is just a place to manifest energy from the Ether.

- Copper material with Tesla's Bifilar-style winding, like a DNA double helix. The electromagnetic field (EMF) after generating a voltage inherently harmful to the generator (it will stop the magnet from rotating - Lenz's law) becomes beneficial.

- The rotor rollers are Copper coated magnets, they will be driven by the voltage on the coil itself, creating resonance.

- The output voltage depends on the speed of the rotor roller and the number of turns.

- The speed of the rotor roller is controlled by a custom frequency, square pulse voltage applied to the control coil.

- This incredible feat is due to the instability of having an AC sine imprint on the plate and a cosine print on the rollers - instability created as the fields conflict causes the rollers to orbit the plate. They are held down by the magnetic field and thrown out by the centrifugal forces, so the rollers do not actually touch the plate when in motion.

- It is a detailed instruction on how to make a genuine Searl Effect Generator with high capacity by yourself..

- In particular, you can make your own Searl Effect Generator in the simplest way (Searl Effect Generator has been simplified), without requiring complicated materials like John Searl's genuine work, but still achieving high performance.